Special Purpose Machine is a device that integrates mechanical automation processing and visual digital control. It is mainly used for drilling, tapping and other processing techniques of various materials. The following is a detailed introduction to non-standard automatic drilling and tapping machines:

1、 Main functions and application scope

Main functions: marking, drilling, chamfering, tapping, returning, threading, etc.Application scope: plastic products, stamping sheet metal, aluminum profile shells, copper products, die-casting alloys, steel parts, etc.

2、 Technical features

High degree of automation: Compared to manual or semi-automatic processing, non-standard automatic drilling and tapping machines have the characteristics of automated mechanical production, which can greatly improve production efficiency.

High processing accuracy: The product has consistent high precision, and using PLC digital control technology, it can be freely programmed according to processing requirements to accurately process parts of different sizes and shapes.

Strong flexibility: As it is a non-standard device, it can be customized according to the specific needs of customers, with strong adaptability.

3、 Equipment composition and working principle

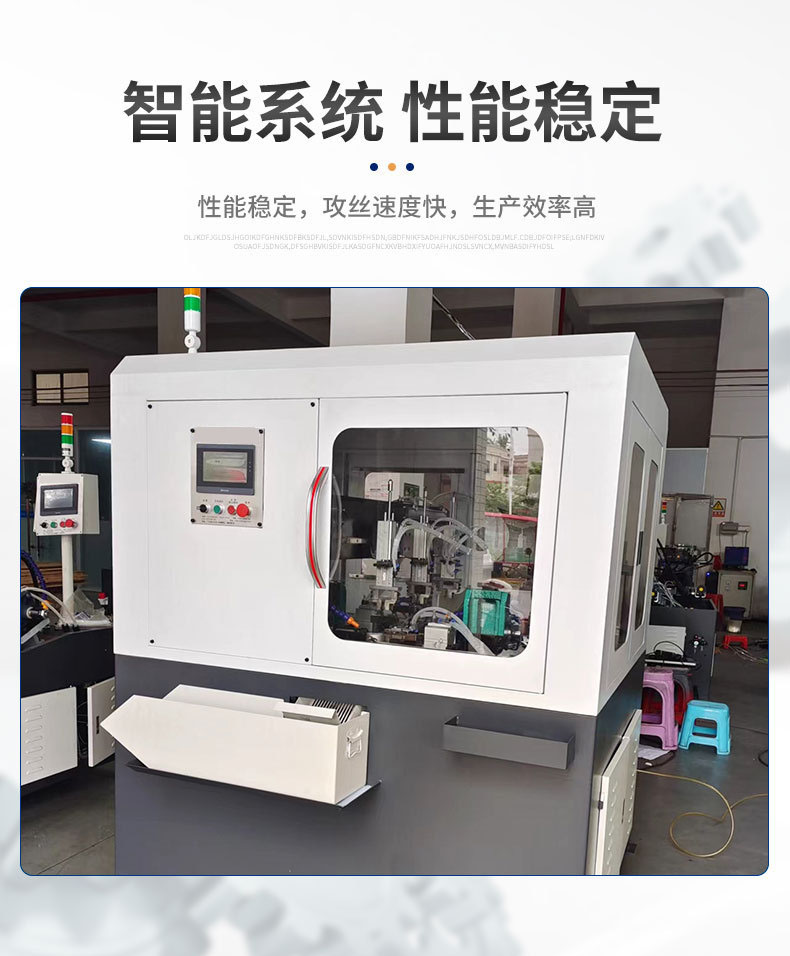

Numerical Control System: Responsible for generating machining programs for hole machining, processing them through computer numerical control software, and controlling the various moving parts of the machine tool.

Spindle system: Provides cutting force, usually using high-speed, high-precision electric or mechanical spindles, equipped with multiple tool clamping methods.

Feed system: controls the feed speed and position of the tool on the workpiece to ensure the smoothness and accuracy of the feed motion.

Cooling system: used to cool the cutting area and tools, reduce cutting temperature, and extend tool life.

Safety protection system: including fully enclosed protective covers, emergency stop buttons and other safety devices to ensure the safety of operators.

4、 Usage performance and technical performance

Performance: The equipment has characteristics such as smooth and reliable movement, stable product quality, maintenance of processing accuracy, and adaptability to the environment.Technical performance: Non standard automatic drilling machines have a certain degree of flexibility and can adapt to changes in product specifications and varieties within a certain range; At the same time, it also has the advantages of reasonable automation level, simple structure, easy manufacturing, low cost, high productivity, high efficiency, and low energy consumption.Overall, non-standard automatic drilling and tapping machines are efficient, precise, and flexible automated processing equipment widely used in drilling, tapping, and other processing techniques

for various materials.