The horizontal multi position rotary table machine is a highly efficient mechanical processing equipment. The following is a detailed introduction to it:

1、 Equipment structure

• Rotary table structure

The turntable is the core component of the equipment, with different numbers of workstations evenly distributed on it, such as 4, 5, 6, 8, 10, 12, etc. Each workstation can hold one workpiece. The turntable is generally made of high-strength steel to ensure its strength and stability when rotating at high speeds and withstanding large cutting forces. For example, an 8-station turntable may have a diameter of around 1-2 meters, depending on the processing capacity of the equipment.

The rotation drive of the turntable is usually achieved by a motor through gear transmission, which can accurately control the rotation angle of the turntable and ensure that each workstation can accurately move to the processing position.

• Machining spindle system

The implementation of functions such as drilling, tapping, reaming, boring, and milling mainly relies on the machining spindle. The spindle system includes a spindle, a tool clamping device, and a spindle drive device. The spindle is generally supported by high-precision bearings to ensure its rotational accuracy. The tool clamping device can firmly clamp various tools, such as drill bits, taps, reamers, milling cutters, etc.

The spindle drive device is usually driven by a variable frequency motor, which can adjust the spindle speed according to different processing requirements. For example, during drilling, the spindle speed may be high, reaching thousands of revolutions per minute; When tapping, the speed is relatively low to ensure the machining quality of the thread.

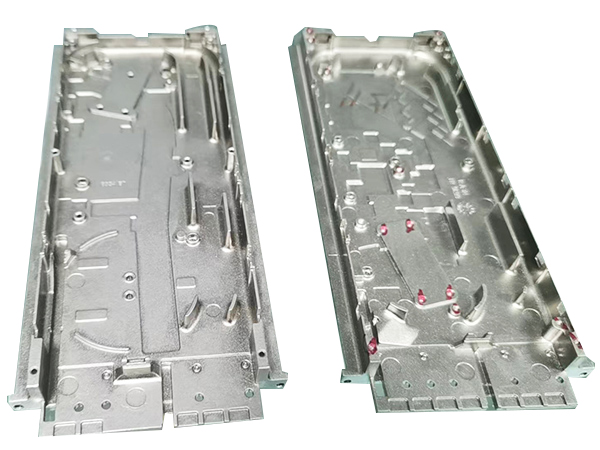

• Fixture system

In order to clamp workpieces, each workstation is equipped with corresponding fixtures. The type of fixture depends on the shape of the workpiece and processing requirements, and common ones include chuck fixtures, pressure plate fixtures, etc. The chuck fixture is suitable for cylindrical or approximately cylindrical workpieces, which are clamped by the contraction of the jaws. The pressure plate fixture uses a pressure plate and bolts to fix the workpiece, making it suitable for processing irregularly shaped workpieces.

The design of fixtures requires the ability to quickly clamp and disassemble workpieces while ensuring their stability during the machining process. For example, some advanced fixture systems can complete the clamping and loosening operations of workpieces in seconds, greatly improving production efficiency.

2、 Working principle

• Workpiece clamping and positioning

Firstly, the operator clamps the workpiece onto each workstation of the turntable. After clamping is completed, the workpiece is accurately positioned using positioning devices such as positioning pins, positioning blocks, etc. The function of the positioning device is to ensure that the workpiece maintains the correct machining position during the machining process and reduce machining errors.

• Processing process

The turntable begins to rotate, sequentially delivering the workpieces to the position of the machining spindle. When the workpiece reaches the machining position, the tool on the spindle begins to machine the workpiece. For example, if drilling is required, the spindle drives the drill bit to rotate at high speed and feed downwards, and the drill bit drills a hole in the workpiece. During the machining process, the coolant system sprays coolant into the machining area to reduce cutting temperature, extend tool life, and flush away chips, ensuring the quality of the machined surface.

After the processing is completed, the turntable continues to rotate and sends the processed workpiece to the next workstation or unloading position. At the same time, the next workpiece to be processed enters the processing position and starts a new processing cycle. This multi station processing method greatly improves the processing efficiency of the equipment and reduces the idle time of the equipment.

3、 Main functions and advantages

• Diverse functions

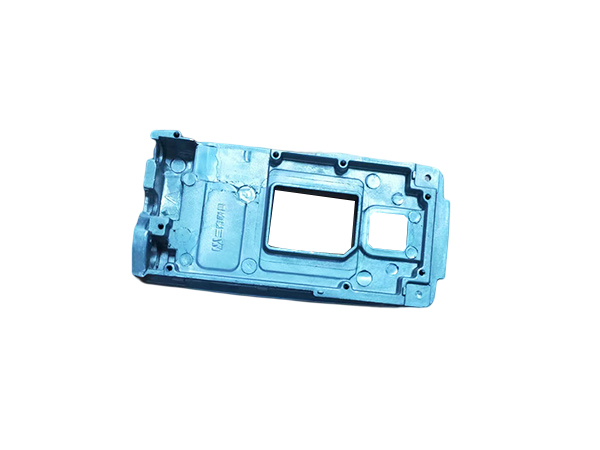

Drilling function: It can process holes of various diameters and depths, suitable for processing connection holes, positioning holes, etc. on mechanical parts. For example, in the machining of automobile engine cylinder blocks, cylinder holes for installing pistons can be drilled.

• Tapping function: capable of processing internal threads, used for manufacturing parts such as nuts, threaded holes, etc. By low-speed rotation of the spindle and feed motion of the tap, threads that meet the standards can be machined on the workpiece.

• Reaming function: used to improve the machining accuracy and surface quality of holes. The reamer rotates inside the hole and performs a small amount of cutting, which can achieve a high level of dimensional accuracy of the hole. It is generally used for machining high-precision mating holes.

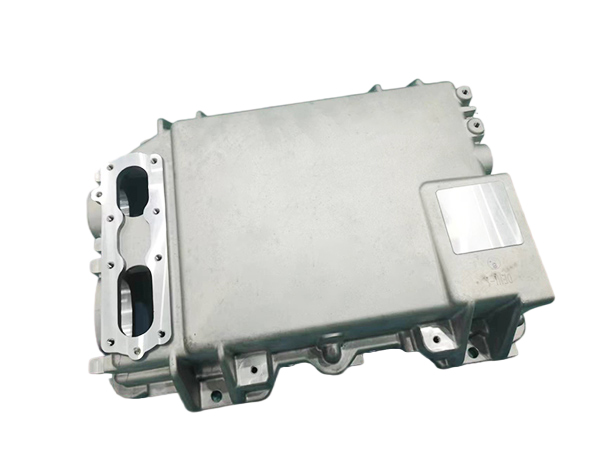

Boring function: It can process larger diameter holes or expand and precision machine existing holes. For example, when machining the bed holes of large machine tools, the boring function can ensure the dimensional accuracy and cylindricity of the holes.

Milling function: capable of processing flat, inclined, groove and other shapes. For example, installation planes on mechanical parts can be milled or complex contour shapes can be machined.

• Obvious advantages

• High efficiency: Due to multiple workstations, operations such as clamping, processing, and unloading can be carried out simultaneously. For example, on a 12 station turntable machine, when a workpiece is being processed at the spindle position, other stations can simultaneously clamp or wait for processing, greatly shortening the processing cycle and improving production efficiency.

• Reduce manual intervention: The equipment has a high degree of automation, from workpiece clamping to processing completion, most operations can be automatically completed by the equipment. This not only reduces the labor intensity of manual operations, but also reduces the impact of human factors on processing quality and improves the consistency of processing.

High machining accuracy: The precise positioning of the turntable and the high-precision rotation of the spindle ensure the precision of machining. By setting reasonable processing parameters, parts that meet high precision requirements can be processed, such as high-precision mold parts or aerospace components.